LM2596 HV Datasheet Schematic & dc to dc buck converter module,

IC LM2596 HV could be an alternative to LM 2596 dc to dc buck converter IC, if later is not available. Thus you can use an IC LM2596 HV dc to dc buck converter for the same purpose. Other than HV i.e, higher voltage operations, it has very similar working and specifications.

The LM2596 HV is a popular voltage regulator/ buck converter IC ideally suited for convenient design of a step−down or you can say step-up switching regulator. It is capable of driving a total load of 3.0 Amps with excellent line and load regulation.

In addition to the 3.3V, 5V, and 12V output version, this power converter has an adjustable output version as well.

In comparison with popular three-terminal linear regulators, the LM2596 HV buck converter is significantly more efficient due to its switch-mode power supply feature, especially when input voltage is high.

The LM2596 HV operates at a higher switching frequency of 150 kHz, which means smaller sized filter capacitors would be needed as compared to lower frequency switching regulators.

If talking of packaging, it is available in a standard 5−lead TO−220 package with several different lead bend options (check datasheet), the TO-263 D2PAK surface mount package and a SOP-8 surface mount package

Also check, LM2596 dc to dc buck converter in detail

Features of LM2596 series:

Some of the main features include a maximum ±4{42041a7992ac3be9e9e29c856254fb498d8c7935d7cf8512da6802e8688e734a} tolerance at output terminals when conditions are as specified, (when input voltage and load conditions are met).

- It is Available in a fixed 3.3V, 5V, 12V and an adjustable output voltage range of 1.20 V − 57 V.

- Maximum of 3.0 A output load current.

- Available in TO-220, TO-263 and SOP-8 packages.

- Wide input voltage range up to 60 Volts.

- A 150 kHz fixed frequency internal oscillator.

- Requires only 4 external components.

- TTL shutdown capability (for digital/ analog ON/OFF)

- Low power standby mode – consumes as low as 30 uA when in standby.

- Built-in thermal shutdown and current limit.

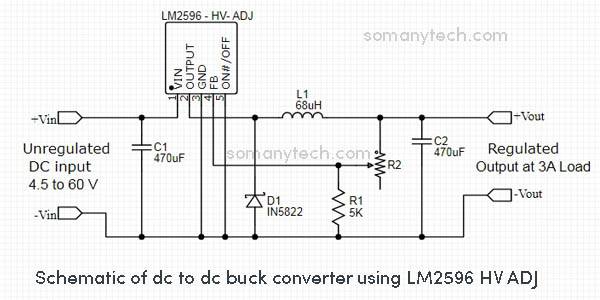

Schematic diagram of LM2596 HV dc to dc buck converter module:

Components required:

IC 2596 HV ADJ TO-220 dip package with heatsink, L1 = inductor = 68uH, R1 = 5kΩ, R2 = variable resistor 100kΩ or higher, C1 = 470uF 63V, C2 = 470uF 63V, Schottky switching diode = IN5822 (any alternative will work).

Check below circuit diagram for adjustable dc to dc buck converter using LM 2596 HV ADJ version of the IC.

The above image clearly shows the circuit connections/ wiring diagram. Please ensure that the input voltage must be (1.5 volts) higher than the required output voltage. Make sure to follow the “Circuit Design Rules” when implementing a PCB (printed circuit board) design.

In general, input could be between 4.5V and 60V. And the output could be derived in the range of 1.20V to 57V, and maximum up to 3 Amps.

The output of the circuit is determined by the FB (feedback voltage). We just needed to add resistor R1 and R2 to the feedback pin(4) as shown in the circuit diagram. The feedback voltage depends on the value of resistor R1 and R2. Thus, by adding a variable resistor, you can control the output voltage according to the following equation:

Vout = Vref(1+R2/R1)

Where, Vref= 1.23 Volts

And, R1 could be between 1KΩ to 5KΩ, choose R2 be a variable resistor.

Also check, 3.7v to 5v Boost Converter Circuit

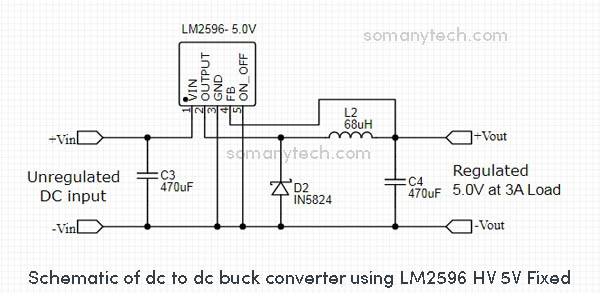

Capacitors C1 and C3 are input filters that stabilize changes in DC input. Also, capacitors C2 and C4 are output filter capacitors.

- If you are working on wide range input and output voltages. Then you must select the output capacitor accordingly (voltage ratings must be higher than that of operating voltage range, in this case 63V rated capacitors).

- Choose capacitor values as shown on this post or recommended in the data sheets of respective ICs.

Check below circuit diagram for dc to dc buck converter using fixed version of the LM2596HV.

This is a 5v fixed version of the IC, you can use 3.3V and 12V versions of IC as well in the above circuit. (schematic would be same for all fixed version of LM2596 HV IC)

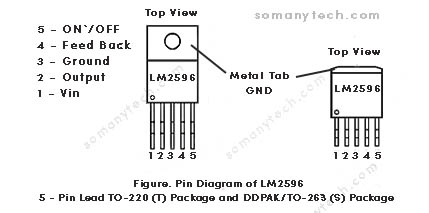

Pinout diagram of LM2596 HV:

There are five total pins on the LM2596 HV, TO-220 and TO-263, as follows:

Pin(1)= Input voltage pin= This pin connects the input supply with the input filter capacitor to prevent voltage spikes at input.

Pin(2)= Output pin (circuit is different for fixed regulators and Adj. version)

Pin(3)= Ground pin = This pin is connected to the ground and a heatsink.

Pin(4)= Feedback pin = This pin returns feedback voltage to the internal comparators for regulation.

Pin(5)= ON/OFF = It is a negative trigger terminal, this means grounding (0 volts) will enable and 1.3 V or higher volts will disable the operations of the internal circuit. This pin is used to standby the voltage regulator circuit to current consumption as low as 30uA.

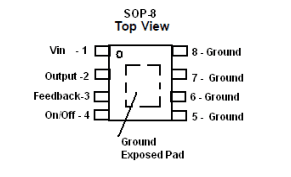

There are eight total pins on the LM2596 HV, SOP-8 package, as follows:

Pin(5), Pin(6), Pin(7), Pin(8) = Gnd =This pin is connected to the supply ground.

Pin(1)= Vin = This pin is connected with unregulated input voltage.

Pin(2)= Vo = Required output is taken from this terminal.

Pin(3)= Fb= Feedback voltage is given to this terminal.

Pin(4)= On/Off = Enable or disable the regulator IC.

Applications of LM2596 HV series:

- In the power supply circuits of li-ion battery chargers.

- Any type of load that takes upto 3 Amperes.

- Any devices where high efficiency step−down or step-up regulators are required.

- Can be used as a high efficiency pre−regulator for better Linear Regulation.

LM2596 HVS Datasheet of IC:

For more detailed technical information on this power converter, check lm2596HVS IC datasheet here.

(All the datasheets and IC’s nomenclature ownership belongs to the respective semiconductor company. The purpose of this post is to elaborate the applications of popular voltage regulators)