All about 775 Motor- Full specification in detail

What is 775 motor? You might have seen 775 written on some popular DC motor. But many people don’t know what actually 775 dc motor is other than it is a motor used for various heavy-duty applications and projects.

The 775 motor is a high-performance DC electric motor that is commonly used in a wide range of applications, including robotics, remote control vehicles, and power tools. The 775 model of DC motor represents a certain ‘size’ of the motor body outer frame. This size is standard for all 775 motors.

The motor is able to deliver a high amount of power while still being relatively lightweight, which makes it well-suited for use in applications that required both higher power and portability. Additionally, it is also known for its high efficiency, which means that it is able to convert a electrical energy into mechanical energy with lesser losses thus doing more work with less energy.

The number 775 is the Size ID of motor accepted as a standard.

Its casing is made of rustproof material mainly steel with some protective coatings, with few plastic parts. It is a high torque high power device for mid to high-power applications generally in robotics, quad-copters, and industrial.

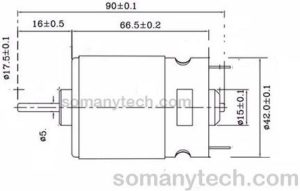

The table below showing specs/ specification of 775 motor:

| Component name | 775 Dc motor |

|---|---|

| Category | Heavy duty dc motor |

| Motor body size (std.) | 66.7 × 42 mm |

| Shaft diameter (std.) | 5 mm |

| Shaft length (generally)* | 14 - 17 mm |

| Operating voltage | 6 - 36 volts |

| Rated voltage | 12 volts |

| No load current (non std.) | ~20 A |

| Speed (non std.)* | |

| Speed at 12 volt | ~4100 rpm |

| Speed at 24 volt | ~8400 rpm |

| Commutation | Brushed/ Brush-less |

Description:

Note that ±1 mm error of body size is acceptable, but not the shaft diameter and length.

The 775 dc motors have a standard size of 66.7 x 42.0 mm. The 42.0 is the outer diameter as the motor is cylindrical, wheres 66.7 mm is its height. The number 775 stands for this standard size. It is in the same fashion to the number with 130 /140 /180 motor.

The shaft size diameter of 5 mm is standard and adopted by almost all manufacturers. The length of the shaft can differ in accordance to the requirements, but a 17 mm shaft is seen commonly. The number of rotation of the motor is dependent on the voltage of operation, i.e RPM ∝ Voltage applied. Rpm is adjusted as per the need of the project. Its nominal operating voltage is 12V but its operation can be ranged from 6 volts to 36 volts.

The no-load current value is an indicator of how much current the motor derives when there is no load applied to it. Thus no-load current is the maximum current that is derived by a motor when it is offload.

Its speed dc motors range from 8300 rpm to 10000 rpm at 24 volts depends on manufacturers mentioned specs, and it is near-linear as we increase voltages. One important thing to keep in mind while buying this motor is to check operating voltage/ current/ speed to meet your requirements for projects and application (generally there is no standard rating followed other than its size).

Both brushed and brush-less model is available in shops. The brushed motor has low cost in comparison with brush-less motors.

A brushed DC motor means that it uses a set of carbon brushes to transfer current to the rotor. On other hand brushless DC motor means that it does not have any mechanical brushes to transfer electrical current to the rotor.

The 775 brushless motor design means that there are no mechanical brushes that can wear out over time, which helps to extend the life of the motor. Additionally, the motor is also able to operate at high speeds without generating significant amounts of heat, that definitely help to prolong the life of the motor by reducing the risk of thermal damage.

Another advantage of the 775 motor is its high torque. Torque is a measure of the motor’s capability to generate rotational force, and the 12 volt 775 motor is able to produce high levels of torque even at low speeds. This makes it well-suited for use in applications that require high levels of starting torque, such as in power tools or robotics.

What is 775 Gear motor?

A 775 gear motor is a modified version of 775 motor, which has a gear-head that combines with the high-performance 775 DC motor and act as a gear reduction mechanism. The outer diameter is maintained to standard size even after adding gear, but length of the geared motor is increased obviously.

It has gear reduction system called as gearbox, which is used to increase the torque output of the motor while reducing its speed. This allows the 775 gear motor to produce required high levels of torque at required lower speeds, making it well-suited for use in applications that require high starting torque and low speed of operation. One of the main advantages of a 775 gear motor is that it can be designed for the precise control of speed and torque which is very important in robotics and automation.

Application of 775 DC motor specs:

- Internet of things devices.

- Robotic projects, RC boats for a hobby.

- In quad-copter due to high speed/ torque.

- Industrial automation and power tool like PCB drilling machines.

FAQ on 775 DC Motors:

Q: How to choose a 775 DC gear motor?

A: If you don’t know how to choose a particular gear motor, then you need to know your requirements about operating voltage, no load speed/ on-load speed, and rated torque. Other than this you can also check about or add a requirement about noise or lifecycle of the product if you are specially ordering from a manufacturer for your custom needs.

Q: How do I determine the required torque for my application?

A: You have to describe the application of the motor you gonna use on your side and the available size/ space in that application. The manufacturer/ supplier could help you in determining it, reason that supplier could have many such proposal similar to your requirements. And they would do a great job on this.

Q: How to increase the lifecycle of 775 motor?

A: Generally gear motor has enough lifecycle, if you are thinking on superior side of product/ application then try considering brushless dc motor also if its in a geared application then consider with planetary gear box.

Q: How to reduce the noise of 775 motor?

A: Reducing noise is quite a tough task, but you could optimize it to lower possible level by lowering the motor speed, by using bearing and lubricant oil. For 775 gear motor use planetary gearbox/ plastic gears.